When’s the last time you analyzed your supply chain? Your supply chain may always be on your mind and you might be involved in it on a regular basis. But when is the last time you and your team committed time to review your supply chain’s performance, identify areas for improvement, and develop an action plan?

Obviously, your supply chain influences nearly every aspect of your business, from quality to turnaround times to profitability. An inefficient or poor-performing supply chain can impact your relationship with customers and even your ability to compete.

When your business depends on the quality of your output, there’s no reason to tolerate substandard quality or protection from your suppliers.

Supply chain analysis should be a regularly occurring event. Unfortunately, in many industrial and manufacturing companies, there’s just not enough time to sit down and dig into the supply chain details. If it’s been too long since you evaluated and updated your vendors, logistics, and other supply chain components, don’t worry. You’re not alone.

Unsure whether your supply chain needs attention? Below are a few warning signs that all may not be well. If any of these sound familiar, now may be the right time to take action.

1. Parts and products arrive with quality defects or in substandard packaging.

Your customers demand quality from you, which is why you expect high levels of quality from your suppliers. While many of your suppliers may consistently meet your high quality expectations, perhaps you have one or two that struggle. They may send products from time to time that aren’t quite to specification or that have obvious defects.

It’s also possible that you have suppliers who haven’t had many actual defects, but you don’t fully trust their quality assurance processes. Perhaps when their shipments arrive at your facility, you notice that the packaging was substandard and vulnerable to any number of quality risks.

When your business depends on the quality of your output, there’s no reason to tolerate substandard quality or protection from your suppliers. Fortunately, there are steps you can take to protect yourself.

One is to work with a packaging consultant in partnership with your supplier. That packaging company could review your vendor’s packaging and quality assurance processes, and then implement a series of actions to improve performance. The packaging company could also take packaging completely off your vendor’s plate. The vendor produces the part and your packaging company handles the rest.

2. You have limited oversight and involvement with your overseas vendors.

The supply chain world has become demonstrably smaller in recent years. If you’re like many manufacturing companies, your supply chain now includes companies from all over the world. The diversity of choice in your supply chain may help you improve your product and your margins, but it can also bring some complicated challenges.

Perhaps the toughest challenge is that it’s simply difficult to keep tabs on your overseas suppliers. You don’t know what their production process or quality assurance protocols are. You can’t communicate with them easily about status updates or order information. If you don’t have personnel in that region, you may not have eyes and ears on the ground to maintain close contact with the vendor.

Since your business outcomes are dependent on the vendor’s performance, you can’t risk having this much uncertainty in your supply chain. One incorrect or defective order could throw a wrench in your entire production schedule.

Since your business outcomes are dependent on the vendor’s performance, you can’t risk having this much uncertainty in your supply chain. One incorrect or defective order could throw a wrench in your entire production schedule.

There are solutions for this issue as well. You may consider hiring an international packaging and supply chain consultant to work as your representative with overseas vendors. The consulting company should have experienced staff on the ground in that country. Their staff can communicate with your vendors and even make personal visits to vendor facilities to ensure quality and timely delivery.

Another option is to set up your own packaging hub in that corner of the world. This is especially helpful if you have a number of suppliers located in one region. You open your own hub staffed with personnel from your packaging consultant. Your vendors ship their products to the hub, where the products are checked for quality and then repackaged to your specifications.

The hub solution is appealing because it injects you into the process at an earlier stage. You see the product and check it for quality within days, or possibly hours, of it leaving the vendor. If there’s an issue, the hub personnel can contact the vendor to get a quick resolution. That’s better than waiting weeks to receive an international shipment only to find that it’s defective.

3. You don’t have a system for analyzing vendor performance and implementing changes.

Are you sure that your vendors are the ones you should be using? It’s a tough question to answer. On one hand, you may need those vendors’ products for your process and they generally meet your needs. On the other hand, perhaps there are other similar vendors that might improve your quality, deliverability, and margins.

The only way to truly answer this question is to have a formal vendor management plan in place. The plan should include performance benchmarks that are clearly communicated to the vendor. If the vendor consistently fails to meet expectations, you either develop a plan to help the vendor improve performance or search for a new vendor.

If you’ve never had a vendor management program in place, this could be difficult to develop, implement, and manage on your own. You may find it helpful to work with an outside partner who has experience managing vendor programs.

4. You can’t get real time updates on the status of your parts and products.

Perhaps the most common vendor-related frustration for manufacturers and industrial companies is that they can’t get good information from their vendors about order status. The more information you have about your supply chain, the more armed you are to make informed decisions about production, scheduling, and more. When you can’t get that information, it makes your job more challenging.

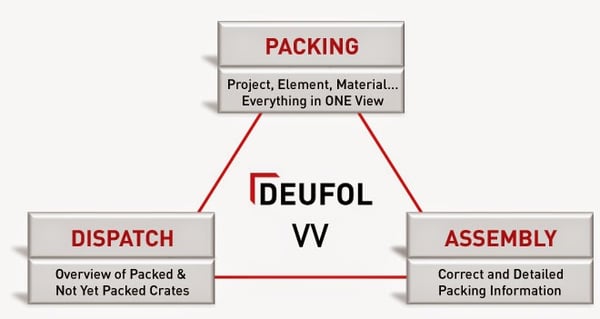

There are a number of steps you can take to improve transparency in your supply chain. One is to work with an outside partner who can help implement tracking technology in your vendors’ facilities. Vendors can scan barcodes as parts and crates leave the facility. That information can be communicated to your software so you get real-time updates on status.

Other potential types of technology include GPS and photo documentation. GPS is most commonly used to provide location information, but it can also provide data on temperature, humidity, vibration, and even air pressure. Photo documentation software allows you to see an image of your product as it is being packed.

This is just a sampling of some of the issues and challenges that may be signs that it’s time to review your supply chain. If you’re experiencing these issues, or others, don’t hesitate to evaluate your system or even to contact an outside partner who can assist with the analysis. There are many strategies, tools, and forms of technology you can use to retake control of your supply chain and boost your quality and profitability. ![]()

Let Us Know What You Thought about this Post.

Put your Comment Below.