Are you fighting to compete in the fast-growing electric vehicle market? If so, you know how competitive the market is. Manufacturers are constantly developing new and improved parts to increase their share. If you don’t keep up, you could lose share and fall behind the competition.

One of the most competitive areas in the EV market is in the battery space. Of course, this makes sense since the battery is perhaps the most top-of-mind component in an electric vehicle.

It’s not just the battery that’s important, though. The battery module containment insulator also plays a crucial role. It not only protects the battery from damage, but it also protects other EV components from the battery itself. As a manufacturer, your battery module containment insulator can make or break your product’s overall quality.

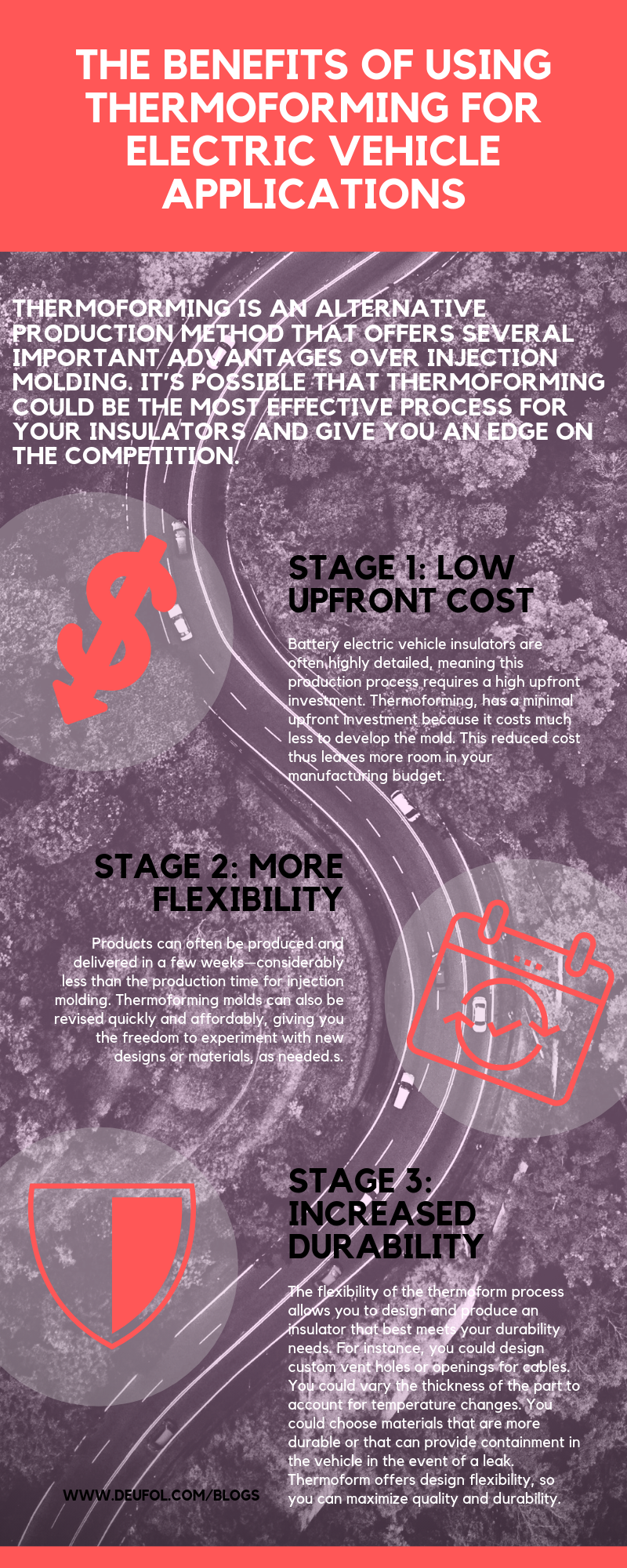

Historically, injection molding has been the default manufacturing process for a wide range of plastic automotive parts, including battery module containment insulators. However, injection molding isn’t the only option. Thermoforming is an alternative production method that offers several important advantages over injection molding. It’s possible that thermoforming could be the most effective process for your insulators and give you an edge on the competition.

The Benefits of Thermoforming

1. Low Upfront Cost

Injection molding involves injecting molten material into a custom mold. This mold has to be designed and produced before any EV components can be manufactured. Battery electric vehicle insulators are often highly detailed, meaning this production process requires a high upfront investment.

Thermoforming, on the other hand, has a minimal upfront investment because it costs much less to develop the mold. This reduced cost thus leaves more room in your manufacturing budget.

2. More Flexibility

The mold design process is the most cumbersome and time-consuming part of the injection molding process. As previously stated, molds are often highly detailed, meaning they require a substantial upfront investment. Any alteration in the design will also require a completely new mold, which can further increase production costs.

Thermoforming offers more flexibility. Products can often be produced and delivered in a few weeks—considerably less than the production time for injection molding. Thermoforming molds can also be revised quickly and affordably, giving you the freedom to experiment with new designs or materials, as needed.

That means you can produce a small batch of insulators or other parts, check for form fit and function, and then make quick, inexpensive changes for the next round. Thermoforming is ideal for designs that could change with trial-and-error, which is often the case in the EV market.

3. Increased Durability

Injection molded components are all produced at a consistent level of thickness. One would assume that those parts would be more durable than their thermoformed counterparts, but that’s not always the case.

The flexibility of the thermoform process allows you to design and produce an insulator that best meets your durability needs. For instance, you could design custom vent holes or openings for cables. You could vary the thickness of the part to account for temperature changes. You could choose materials that are more durable or that can provide containment in the vehicle in the event of a leak. Thermoform offers design flexibility, so you can maximize quality and durability.

Think thermoforming might be right for your automotive EV application? Deufol can help you design and produce high-quality, cost-effective battery module containment insulator that can keep you ahead of the competition. Let’s connect soon, and start the conversation. ![]()

Let Us Know What You Thought about this Post.

Put your Comment Below.